-

Dōgo Onsen Honkan+

-

Asuka-no-Yu+

-

Tsubaki-no-Yu+

Traditional Ehime handicrafts displayed at the Dōgo Onsen Annex Asuka-no-Yu.

Dōgo Onsen Front Page > Dōgo Onsen Annex Asuka-no-Yu > Traditional Ehime handicrafts displayed at the Dōgo Onsen Annex Asuka-no-Yu.

Entrance

Entrance / Shade of Temple Gate Zeolite washi-paper (Seiyo City) Sato Yukari(Rikū)

She started producing a new method of washi paper called "Zeolite washi" in Ikazaki, Uchiko Town, where she grew up and where handmade washi has been produced. Currently, she has a studio in Seiyo City, and is engaged in production. Her unique expressions, such as partitions that blur the boundary between inside and outside while maintaining the continuity of space, have received high acclaim both in Japan and abroad. The theme of the shade for here is the "Temple Gate" that greets visitors at the entrance.

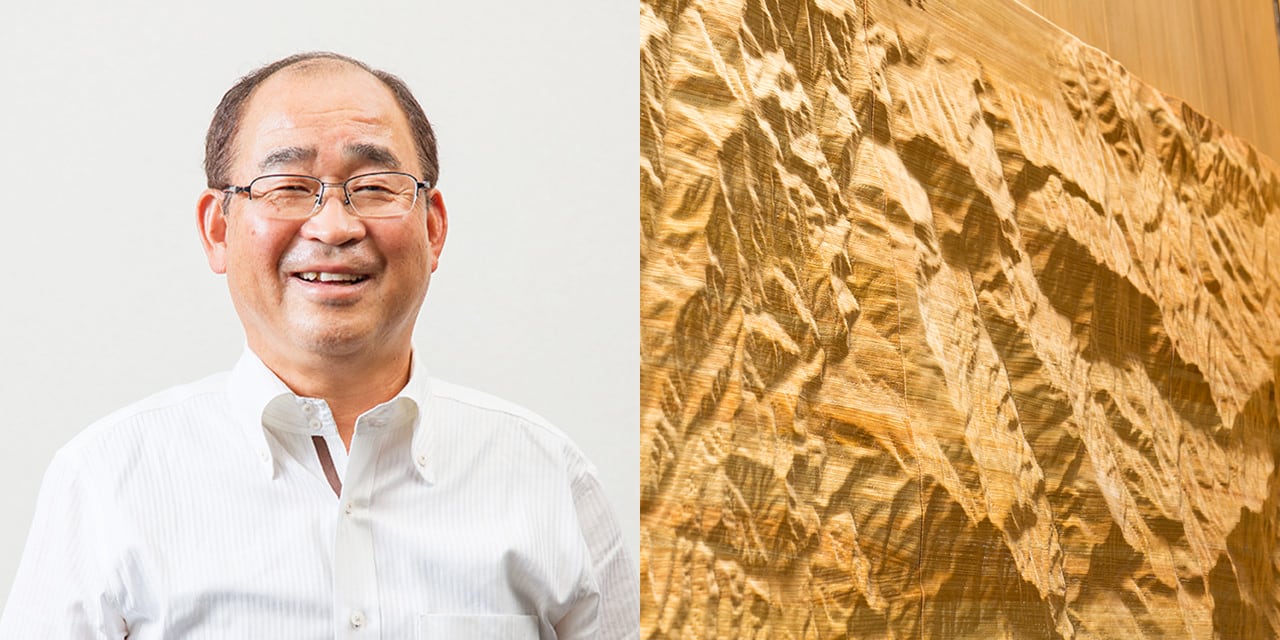

Entrance /Wall Mural Japanese-style Nails (Wakugi)(Matsuyama City) Shirataka Okimitsu(Ehime traditional craftsman)(Shirataka Cutlery Workshop)

‘Wakugi nails’ are iron nails used in Japanese wooden architecture and are an indispensable material for restoring and reconstructing ancient buildings. The number of craftsmen of wakugi nails has been decreasing in Japan, so the craftsmen of wakugi nails are quite precious. Shirataka Yukinori, his father, has restored and rebuilt famous national treasures and important cultural properties such as Yakushiji Temple, Muroji Temple, and the Daigoku-den Hall of Heijo Palace using his nail skill. In this facility, his son, Okimitsu is decorating the huge woodblock mural that adorns the entrance with those Japanese-style nails.

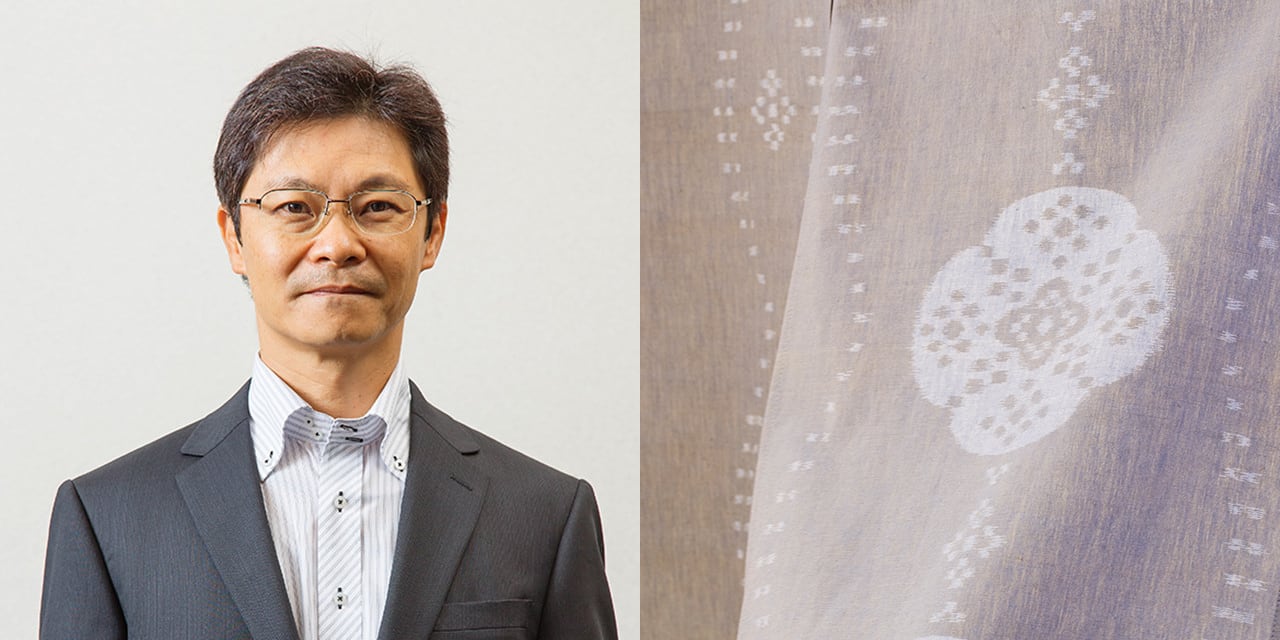

Entrance /Shop Curtain Iyo-kasuri (ikat fabric)(Matsuyama City) Iyo Textile Cooperative Association(Shirakata Kōgyo Corporation)

Iyo-kasuri" is one of Japan's three major types of kasuri fabric. The warp and weft threads are dyed in advance, and a pattern is woven into the fabric, creating a unique texture that looks as if it has been blurred. The production of Iyo-kasuri used to be the largest in Japan during the Meiji period (1868-1912), but now only Iyo-kasuri Kaikan (Shirakata Kogyo) produces Iyo-kasuri. The facility is involved in the production of "noren", shop curtains, that welcome guests at the entrance to the men's and women's bathrooms.

Bathrooms

Bathrooms / Ceramic Mural Tobe Ware(Tobe Town) Yamada Hiromi(National Traditional Craftsman)(Kiyoshi Kiln)

Tobe ware is porcelain made mainly in the town of Tobe where more than 100 Kilns produce keeping traditional ways. In recent years, the number of women and young artists has been increasing and a new trend has been growing. Yamada Hiromi, the only nationally designated traditional craftsman in Tobe Town, has been active in a wide range of activities, creating works of various sizes. At this facility, she has created a huge 5.4m x 2.7m ceramic mural in the men's and women's bathrooms.

Bathrooms / Open-air bath wall staging Hime Hinoki-cypress Decorative Panel(Matsuyama City) Kōno Industrial Corporation

Ehime Prefecture boasts the second largest production of Japanese cypress in Japan. In order to make more use of Hinoki in daily life, "Decora Panel" was created to solve the problem of "cracking," which has been a problem with conventional solid wood. Visitors can enjoy the color, texture, and fragrance of Ehime-hinoki as if they were in nature. In this facility, Decora Panel is used to decorate the walls of the open-air bathrooms, which are in a humid environment where cracks are likely to occur.

Bathroom / Lantern Kikuma roof tiles(Imabari City) Kikuchi Haruka(Kikugin Tiles Co., Limited)

Kikuma Tiles are said to have been first manufactured in the Kamakura period (1185-1333). Kikuma tiles are also called "ibushi-gawara" (smoked tiles) because of their shiny silver color, and are used at Matsuyama Castle, Dōgo Onsen Honkan, Kyoto Imperial Palace, and the Imperial Palace because of their beauty, waterproofing, and cold resistance. Although production has been declining in recent years due to the decrease in the number of tile-roofed houses, the company is actively working to develop new products such as accessories and daily necessities. At this facility, they are producing andon lanterns for the open-air bathrooms.

Special Bathrooms / Fine Bamboo Screen Iyo-su-bamboo Screen(Niihama City) Ihara Keiko(Ehime traditional craftsman)(Suki-su Workshop)

A "bamboo screen" is a tool for scooping Japanese paper. It is made in the area where handmade washi is produced, and the one made in Ehime is called "Iyo-su". The "bamboo screen" is woven using bamboo strips thinner than a bamboo screen and special threads for the screen, and it takes a long time to weave one screen because of the delicate handwork. The facility is making use of this technique to create the "Iyo-su bamboo screen" that softly separates the special bathroom from the Japanese-style room.

Resting lounge

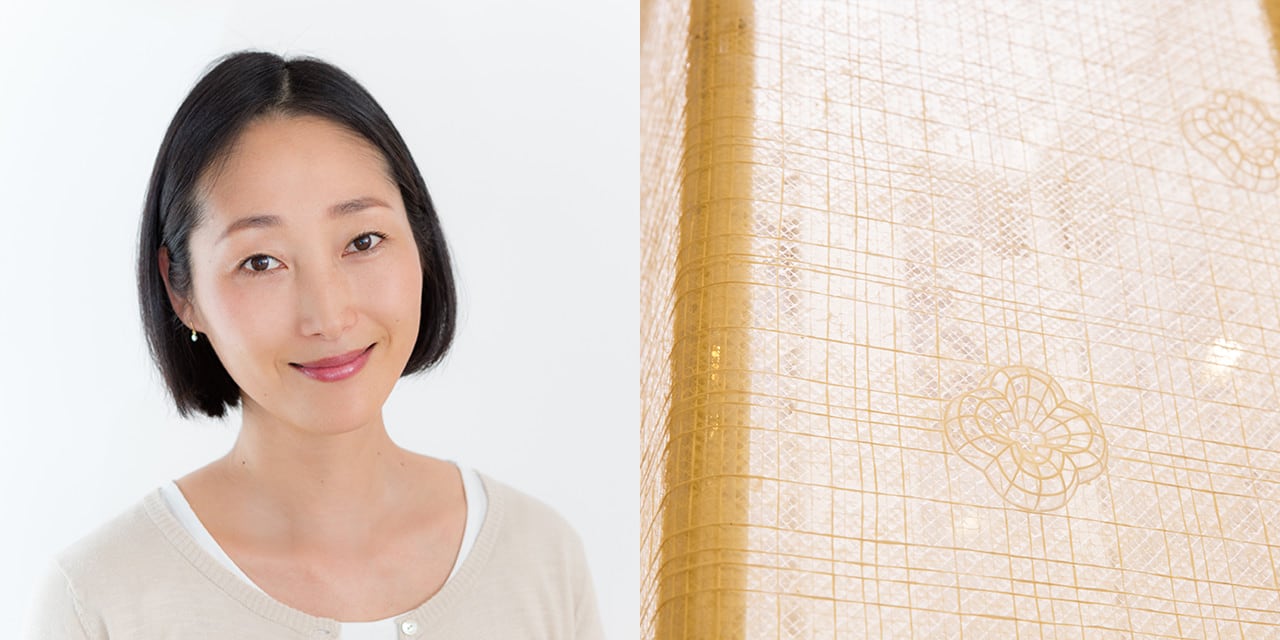

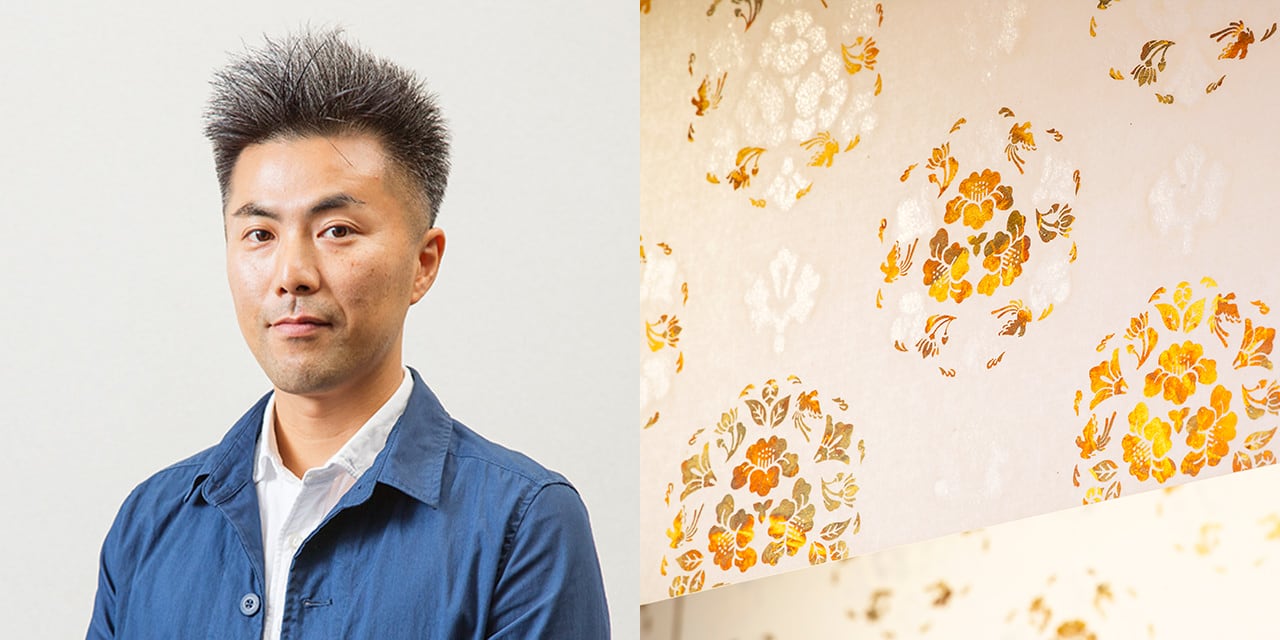

Large Resting Lounge / Ceiling shade, Lighting, Open veranda lighting Ozu-washi paper(Uchiko Town) Saitō Hiroyuki(Ikazaki Group Co., Limited)

Ozu washi Paper is a nationally designated traditional craft. It has such a long history that a record of it can be found in the Engishiki written in the Heian period (794-1185). Gilding Washi" is the result of the fusion of Ozu Washi and gilding (metallic foil) processing technology. The gentle and soft expression of washi and the presence of gilding foil create a unique expression. The theme of this facility is "Jukoku,"meaning Blessed Country and he is working on the ceiling hanging shades and lampshades for the Large Resting Lounge.

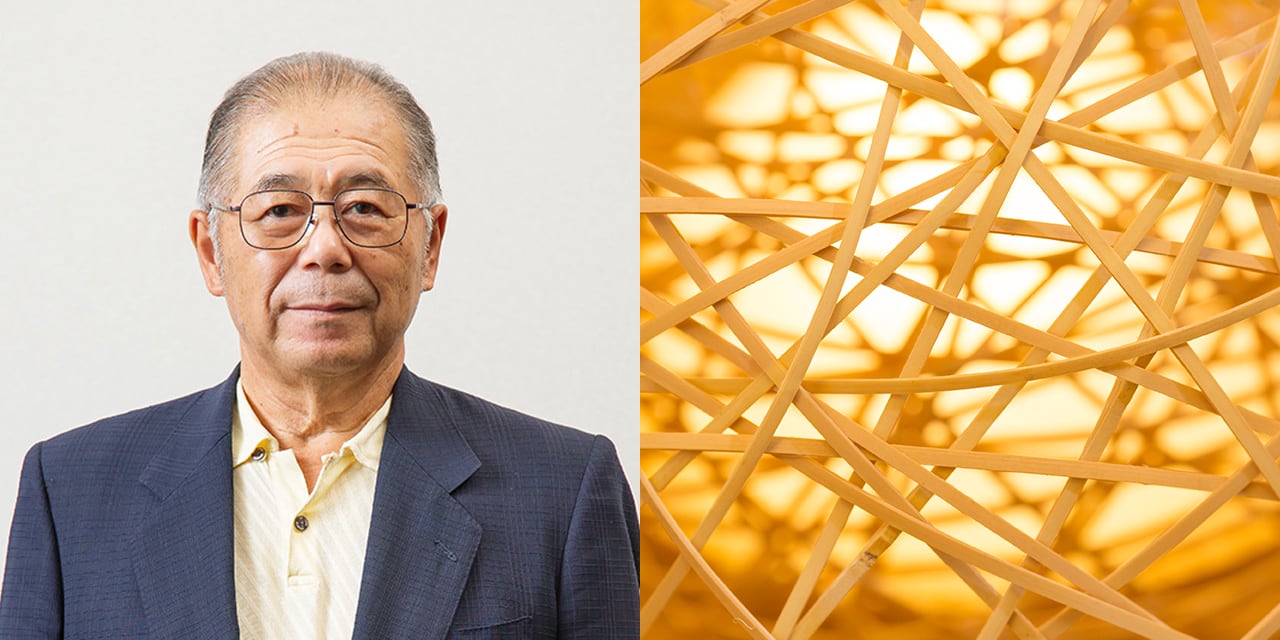

Large Resting Lounge / Lantern Iyo Bamboo Crafts(Matsuyama City) Nishikawa Shizuhiro(Ehime traditional craftsman)(Toratake Workshop・Nishikawa)

A legend says that Prince Shōtoku, who visited Dōgo Onsen, taught Iyo bamboo craftsmen how to weave. ‘Yachara-weaving’, in which bamboo strips are irregularly pulled out to finish the woven basket without using a mold, is a distinctive feature of this craft. The works woven by skilled craftsmen are highly acclaimed for their gentle, handmade texture. The facility produces andon-lanterns as lights for the Large Resting Lounge to create the atmosphere of “Jukoku”.

Private resting room / Wall Decoration(The legend of an Egret) Iyo Mizuhiki (Decorative Japanese codes)(Shikokuchuo City) Andō Kayoko(Ehime traditional craftsman) Murakami Mieko(Ehime traditional craftsman) Tōchi Yōko(Ehime traditional craftsman) (Iyo Mizuhiki Kinpū Cooperative)

Shikokuchuo City is one of the two major mizuhiki production centers along with Iida City in Nagano Prefecture. Iyo-no-Mizuhiki" is said to have originated in the Heian period (794-1185). Various forms of mizuhiki are made by "tying," "weaving," and "coiling" mizuhiki, which are then combined to create handicrafts. At this facility, works using Iyo mizuhiki craft techniques are created under the theme of the legend of an egret in Dōgo hot springs.

Private resting room / Wall Decoration (The legend of the Precious Stone) Tsutsugaki-dyeing(Yawatahama City) Wakamatsu Satoshi(Ehime traditional craftsman)(Jizaiku-konya (all handmade dyeing) Wakamatsu Flag Shop)

In tsutsugaki-dyeing, patterns are drawn by hand on a Japanese paper tube filled with glutinous rice paste, which is then squeezed out. The characteristic feature of this technique is that the paste leaves a white background, allowing lines and outlines to be expressed that do not appear on paper stencils. Jizaiku Konya Wakamatsu Hataten has a history of more than 190 years since the end of the Edo period, and currently produces a wide variety of works, including festival costumes, shrine crests, banners, and Tsuji banners. At this facility, they are decorating the walls of the private rooms with original works based on the theme of the legend of the Precious Stone, in which Okuninushi no Mikoto and Sukunahikona no Mikoto appear.

Private resting room / Wall Decoration(The legend of Prince Shōtoku) Imabari Towel(Imabari City) Fujitaka Co., Limited

Imabari Towel" has developed its dyeing technology against the backdrop of the high-quality water from the Takanawa Mountains. Today, it forms one of the largest towel production areas in Japan. Fujitaka Co., Ltd. has a history of more than 90 years in the towel industry, and has led the industry with its technical capabilities. This facility is themed on the legend of Prince Shotoku's coming to bathe, and challenges new expressions of Imabari towels using the "Gosai-ori" technique, which realized the world's first full-color expression in yarn-dyed Jacquard weave towels.

Private resting room / Wall Decoration(The Imperial Visit) Sakurai Lacquer Ware(Imabari City) Watanabe Shūhō(Ehime traditional craftsman)(Sakurai Lacquer Ware Cooperative)

Sakurai lacquerware was introduced to Sakurai by a shipping agent in the late Edo period. It is said that Sakurai Lacquerware gathered technicians from Wajima, Kishu-Kuroe, and other advanced lacquerware regions, and incorporated the best of the regions from all over the country. Today, many people still enjoy Sakurai lacquerware because it is possible to obtain high quality lacquerware at a relatively low price. The theme of this facility is the many emperors who visited Dōgo Onsen during the Asuka and Heian periods, and they are taking on the challenge of creating works of an unprecedented size and new spatial-expression.

Private resting room / Wall Decoration(Yugeta (hot springs) in Iyo) Saijo Danjiri (potable shrine) Scripture(Saijo City) Ishimizu Shinji(Ehime traditional craftsman)(Ishimizu Engraving Studio)

“Saijo Danjiri Sculpture” has developed along with the "Saijo Festival" held every year in mid-October in Saijo. Ishimizu is the fifth generation of danjiri master carvers, and the flowers, birds, myths, and dragons he carves using as many as 100 different types of carving knives seem to come to life. This facility uses the techniques of danjiri carving to depict the bustling atmosphere of the time when Dōgo Onsen was described in the Tale of Genji as "Iyo no Yugeta" (the hot springs of Iyo).